Quadtec - Machining Technology

Precision others can only dream of!

Technologies and Services

From the right choice of the material over the feasibility of turned and milled parts to the assembly of entire components and even beyond, H & W Quadflieg advises you in a competent and exhaustive way. It is very important for us to support you in making your ideas and projects become workable and cost-efficient.

Machine Park

H & W Quadflieg has a high-quality, cutting-edge machine park. It contains 16 different turning and milling centers, which are operated by our highly experienced and well-trained team. We manufacture orders from 5 to 5,000 parts for the markets: mechanical and plant engineering, aerospace, robotics, medical applications, optical applications and chemical industry. We manufacture the highest precision: the production to 0.01 mm is our daily business. H & W Quadflieg fulfills your most demanding orders up to 5-axis simultaneous manufacturing.

Overview of the machine park:

Turning&Milling Centers- DMG Beta 800 TC complete processing from 50 to 300 mm with counter spindle

- 1 × CNC Turning Machine DMG CTX 620 700 mm diameter * 1.000 mm turning length, power-driven tools

- 1 × CNC Turning Machine DMG CLX 450 power-driven tools, Y – Axis, bar loader

- 1 x CNC Turning Machine CTX 310, 40 mm diameter, power-driven tools, bar loader

- 2 × CNC Turning Machine Traub TNA 500 500 mm diameter * 900 mm turning length

- 1 × CNC Turning Machine DMG CTX 500 500 mm diameter * 800 mm turning length

- 2 × CNC Turning Machine DMG CTX 400

- 2 × CNC Machining Center DMG DMU 80 P 5-shaft 800 mm round table ~60 tools

- 2 × CNC Machining Center DMG DMU 70V 5 shafts CNC round table 700 mm diameter with internal coolant feature

- 1 × CNC Machining Center DMG DMU 65 P 5-shaft with CNC swiveling round table 650 mm diameter

- 1 × CNC Machining Center DMG DMU 50V 5-shaft with CNC round table 500 mm diameter

- 1 x CNC machining centre Hermle C 400 U 5 axes CNC swivel rotary table 650 mm

- 2 x 3D Coordinate Measurement Machine Mitutuyo, hand-guided and CNC driven in air-conditioned measuring laboratory

- Surface Measuring Machine Mitutoyo

References

Our precise and accurate way of working is very much appreciated by our long-term customers active in various industrial fields. They particularly value H & W Quadflieg's tradition, the high precision and speed of the fulfilled orders as well as our competent advice with convincing cost-benefit-calculation.

Our world-wide customers trust the precision and tradition delivered by H & Q Quadflieg, Aachen, Germany (extract):

Jenoptik, Wittenstein, Schloemann-Siemac, Kuka, RWTH Aachen, Minibea Intec , Novopress, SIG Combibloc, Franklin Electric, Luneau Technology France

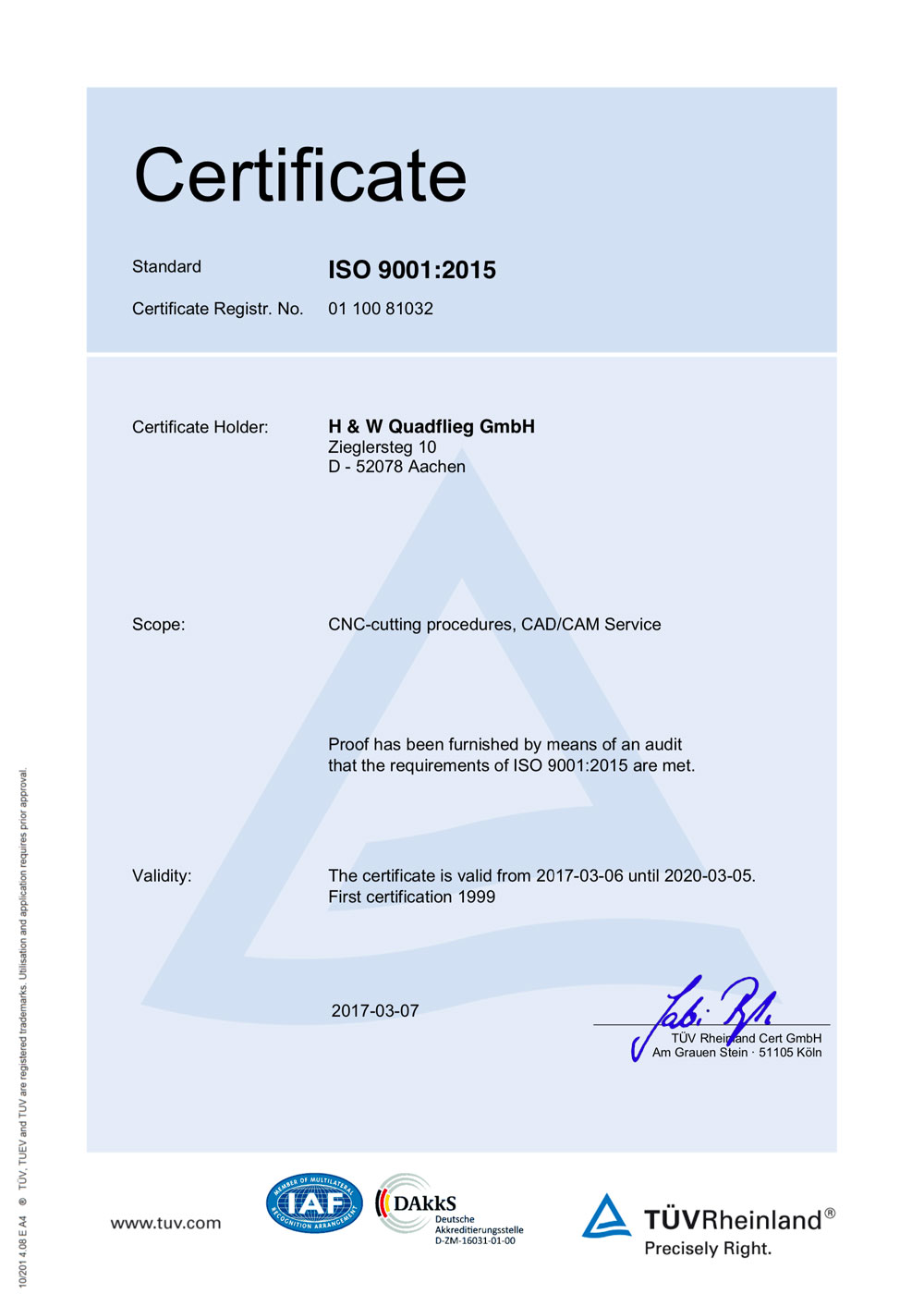

Certificates

We produce your components with precision and accuracy, we monitor and assure the quality of our work with our ISO 9001: 2015 certified quality management system.

About us

H & W Quadflieg GmbH is a traditional, family-owned company active in the field of sophisticated CNC turning and CNC milling technology as well as cutting-edge 3D measurement technology that has been established at the technology location Aachen in Germany for 60 years.

H & W Quadflieg manufactures high-precision ready-to-install machine parts according to customer´s drawings or CAD models. H & W Quadflieg has a machine park of currently 16 different turning and milling centers which can process materials ranging from stainless steel over plastic, non-ferrous metals, titanium to hardened materials. Under the brand name "quadtec", H & W Quadflieg manufactures small and medium size series of exceptionally high precision on state-of-the-art 5-axis machining centers. The manufactured volumes range from 5 to 5,000 pieces with dimensions starting at 3 mm up to 700 mm for small and larger parts weighing up to 250 kg.

H & W Quadflieg manufactures high precision parts for the end markets mechanical engineering, aerospace, robotics, for applications in medical and optical markets as well as for the chemical industry. H & W Quadflieg measures high complex and complicated position tolerances as well as free-formed surfaces in an air-conditioned 3D measurement room, advises customers on the feasibility of turned? and milled parts, regarding the assembly of components and beyond. For hardening, painting, polishing, anodising and other services, H & W Quadflieg cooperates with a range of competent and certified partner companies and thus, is able to offer its customers complete manufacturing from a single source.

H & W Quadflieg is approved by TÜV Rheinland/ Germany for the re-stamping of certified raw materials. Test reports with several hundred testing points are our daily business. H & W Quadflieg has been ISO-certified for more than 20 years, and currently in its version 9001: 2015.

High-Tech Location Aachen, Germany

Aachen is a major business and technology location in Germany, where many well-known companies, world-renowned industrial facilities, universities and research centers are located. The site is directly adjacent to the Netherlands and Belgium with whom business cooperations have been led for many decades. The region benefits from many governmentally driven funding projects.

The immediate geographic proximity to one of Germany's and worldwide most important technological university centers, the RWTH Aachen University, its campus with the various clusters active in fields such as mechanical engineering, lightweight technology etc., provides you access to the current state-of-the-art of research and development at all times. On request and if necessary, personal contacts can be established.

This technological infrastructure is unique in the world and enables state-of-the-art technology transfer between business and science. With 60 years of tradition and experience in precision manufacturing, we are supporting the mechanical and plant engineering sector in the 3rd generation as a reliable and precise partner for your developments.

The imperial city of Aachen, Germany, is also the cradle of mechanical engineering and brought forth historical greats such as Prof. Hugo Junkers (aircraft construction), Prof. Herward Opitz (machine tool engineering) and Prof. Georg Menges (plastics processing), to only name these three. Renowned research institutes such as Fraunhofer IPT, Fraunhofer ILT and Fraunhofer IME are based in Aachen today, and modern vehicle manufacturers such as Streetscooter and e.Go Mobile have chosen Aachen as their headquarters. The Ford Europe R& D Center is located in Aachen. Thus, Aachen is a popular destination with regards to technological, historical (capital of Charles the Great) and aesthetical aspects, as well as an interesting place of work with international reach.

News

-

Start-up and training for the new machine

In May 2019, our experts Mr. Gubien and Mr. Röpke Jansen were intensely trained at Mitutoyo on the new CNC measuring machine. After the training units, the machine was successfully put into operation and we are now looking forward to your orders!

-

New CNC measuring machine

We are very happy to put our new CNC measuring machine Mitutoyo Crysta apex 574 into operation.

Further details about the machine can be found under „Machine park“.

-

Company Run

In September 2018, the H & W Quadflieg team participated in the Company run in Aachen, Germany.

The team successfully accomplished 10 km. Bravo to the athletes and see you there again next time!

Career

“Precision and tradition“ with H& W Quadflieg: H & W Quadflieg is a family-owned company that has been relying on the high-tech location of Aachen, Germany for decades. Our team of currently 24 employees is the main constituent of our success story. Therefore, we are always looking for new qualified and motivated employees who are looking for career challenges.

We offer our employees a secure job, the opportunity for continuous training possibilities as well as independent and autonomous work.

Join our dedicated and experienced team and continue the success story of our family-owned business together with us.

We look forward to meeting you in person!

For more information about our internships, training places and job offers, please contact us directly.

Contact

Guido Quadflieg

CEO and Managing Director

Stephan Engel

Head of Production